ARE YOU OF LEGAL VAPE AGE?

Please confirm that you are of legal age to purchase vaping products to access our site.

Please confirm that you are of legal age to purchase vaping products to access our site.

Some items are no longer available. Your cart has been updated.

This discount code cannot be used in conjunction with other promotional or discounted offer.

Abstract

Introduction

1. New Filter Materials

2. Preparation Processes

3. Conclusion

This paper briefly introduces several common filtering materials used in VAPEPIE Vape filters along with their characteristics. It outlines the preparation processes for various fiber materials and non-woven fabrics, and provides an outlook on the application prospects of Vape filter materials.

Vapes are devices powered by rechargeable lithium-polymer batteries that drive an atomizer. They primarily work by heating the e-liquid in a reservoir to produce an aerosol that is inhaled into the body, simulating the smoke and sensation of traditional cigarettes. Unlike traditional cigarettes, Vape liquids do not contain tar, which eliminates risk factors for cancer, chronic obstructive pulmonary disease (COPD), and other conditions associated with smoking. However, Vapes still contain nicotine, the primary addictive substance in tobacco. Thus, using Vapes does not reduce nicotine intake, and dependency on tobacco remains unchanged. Internationally, there is ongoing debate about whether Vapes can aid in smoking cessation. From a mechanistic perspective, they can reduce the harms associated with traditional cigarette smoking. Therefore, optimizing and exploring Vape filter materials to minimize harm to the human body is essential.

Common filter materials for cigarette mouthpieces include white nano-filter sponges, primarily used in Vapes and various mouthpieces to filter smoke, tar, and other substances. This study explores the application of novel materials in the internal storage section of Vapes for e-liquid, where the liquid is adsorbed. These materials must withstand high temperatures while providing filtration during e-liquid evaporation to reduce hazards. Figure 1 shows a physical image of the filter material.

Aramid (polyphenylene terephthalamide) is a high-tech synthetic fiber that integrates multiple excellent properties, including high strength, high-temperature resistance, acid and alkali resistance, insulation, and anti-aging. It is widely used in composite materials, special protective clothing, electronic equipment, and related fields. Meta-aramid (poly(m-phenylene isophthalamide)) is a type of aramid with outstanding flame retardancy and heat resistance. At temperatures below 205°C, it maintains reusable heat resistance; above 205°C, it retains high strength. Additionally, meta-aramid has a high decomposition temperature, ensuring no melting occurs under high-temperature conditions. It also exhibits excellent resistance to most chemicals, including high-concentration inorganic acids, and good alkali resistance at room temperature. These advantages enable the use of needling methods to reinforce fibers, creating a fluffy structure with numerous micropores through fiber entanglement. This structure is suitable for Vape filter materials, meeting high-temperature requirements while providing filtration.

Figure 1 Actual picture of new filter material

P84 polyimide fiber is a flame-retardant, heat-stable fiber material with a natural golden-yellow color. Its properties are enhanced by its fineness and irregular (leaf-shaped) cross-sectional structure, which maximizes the fiber surface area and improves filtration performance. P84 polyimide fiber offers stable heat resistance, with filter materials prepared from it capable of withstanding up to 260°C without changes in mechanical properties. It is primarily used in gas purification processes such as asphalt mixing, cement kilns, drying, combustion, smelting, coal-fired boilers, and waste incineration, especially in high-emission scenarios. It can be blended with other fibers to leverage their respective strengths. However, P84 is more expensive than similar fibers and is not resistant to hydrolysis.

Polypropylene is a thermoplastic resin obtained from propylene polymerization, appearing as a white, transparent, wax-like substance that is non-toxic, odorless, and tasteless. It is a highly crystalline, lightweight material. Polypropylene is mainly used to produce melt-blown fabrics, which are the core component of masks. Fiber diameters can reach 1–5 μm, featuring a unique capillary structure with high porosity, fluffiness, and wrinkle resistance. This increases the number of fibers per unit area and surface area, providing excellent filtration, shielding, insulation, and oil absorption properties. It is applicable in air and liquid filtration materials, isolation materials, mask materials, thermal insulation materials, oil absorption materials, and other fields.

Acetate fiber is a man-made fiber spun from cellulose acetate, including diacetate and triacetate fibers. In these fibers, most or all hydroxyl groups on the cellulose rings are acetylated. The longitudinal structure is smooth and cylindrical with stripes, while the cross-section is elliptical. Due to low crystallinity and lateral order, acetate fibers have poor breaking strength, which is even lower in wet conditions. However, they exhibit high elongation at break and superior elastic recovery compared to viscose fibers. They also possess good thermal stability, hygroscopicity, breathability, and other advantages, making them popular in the apparel design industry.

Polytetrafluoroethylene (PTFE) fiber is a synthetic fiber produced from PTFE resin through spinning or by cutting or fibrillating films. In its molecular structure, the larger volume of fluorine atoms compared to hydrogen atoms, combined with strong carbon-fluorine bonds, stabilizes the carbon-carbon backbone. This provides PTFE fibers with superior chemical stability and corrosion resistance compared to other synthetic fibers, along with a high operating temperature. It also offers good weather resistance and bending resistance but has poor dyeability, thermal conductivity, wear resistance, a high thermal expansion coefficient, and a tendency to generate static electricity. It is mainly used for high-temperature dust filter bags, highly corrosive gas or liquid filtration materials, fillers, sealing tapes, self-lubricating bearings for pumps and valves, reinforcement for perfluorinated ion exchange membranes in alkali production, and rocket launch pad tarpaulins.

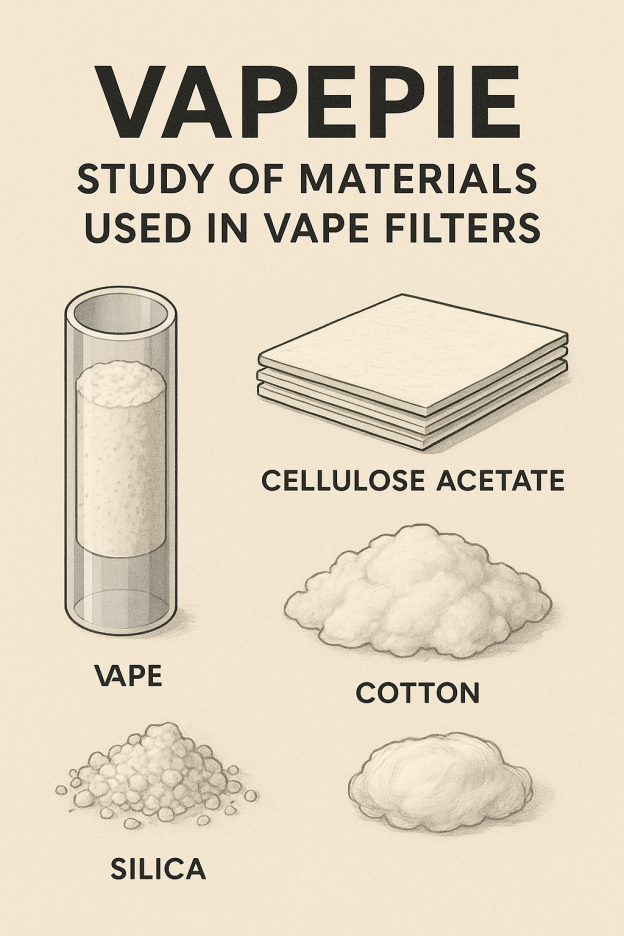

The melt-blowing method is a processing technique for preparing ultrafine fiber non-woven fabrics, similar in principle to electrospinning. It involves rapid stretching and solidification of freshly extruded polymer melts using high-speed hot airflows. The process is straightforward, allowing direct conversion from spinning to non-woven fabric, as illustrated in Figure 2. At 240°C, polymer masterbatch is melted in an extruder and delivered to the melt-blowing die via a metering pump, which controls the melt flow to the nozzles. The spinneret consists of capillary tubes spaced less than 1 mm apart, with diameters of 0.2–0.4 mm. Compressed air at 250–300°C enters from both sides, applying supersonic airflow (over 550 m/s) to the emerging polymer, drawing it into filaments of 1–10 μm in diameter. As the hot air flows downward, it mixes with ambient air to cool the fibers, which solidify into short, fine fibers distributed in a three-dimensional structure. This method is primarily used for preparing polypropylene/polylactic acid non-woven materials.

Figure 2 Working principle of meltblowing

1—screw extruder; 2—metering pump; 3—sprinkler; 4—air duct; 5—winding device; 6—air system

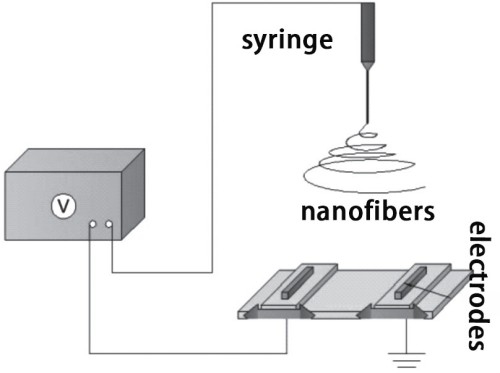

Electrospinning is a specialized form of electrostatic atomization of polymer fluids. It involves placing a special polymer solution or melt in an electric field, where it is ejected and spun into fibers. The atomized material forms very small polymer jets rather than droplets, enabling long-distance flow and eventual solidification into fibers. This results in small pores, high porosity, and large specific surface area, with applications in environmental protection, smart textiles, and energy conversion, as shown in Figure 3. Under the electric field, droplets at the needle tip transform from spherical to conical, extending into fiber filaments. Polymer filaments with nanoscale diameters are typically produced via electrospinning. High-temperature-resistant polyimide fiber filter materials are generally prepared using this method or in combination with other processes to achieve desired performance.

Figure 3 Working principle of electrospinning

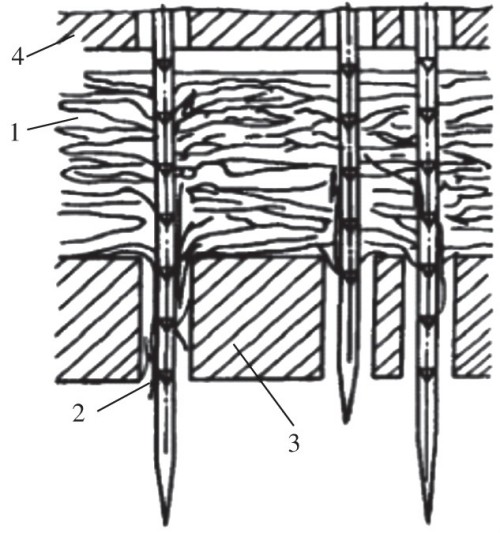

Non-woven needling technology involves repeated puncturing of a fiber web with needles to form a non-woven material with specific areal density and strength, achieving mechanical reinforcement. It accounts for about 30% of non-woven production lines. The process, as depicted in Figure 4, uses triangular-section needles with barbed edges to puncture the fiber web repeatedly. Fibers from the surface and inner layers are pushed into the web by the barbs and compressed due to inter-fiber friction. The inserted fiber bundles remain in the web upon needle withdrawal, leading to increasing fiber entanglement, enhanced overall strength, and the formation of a needled non-woven fabric with specific strength and thickness. Needled non-woven fabrics exhibit good breathability, filtration, and mechanical properties, widely used in industrial and household non-wovens such as filter materials, building waterproofing, and blankets. Tests by Zhao Bo at Zhongyuan University of Technology on polypropylene non-woven needled filter materials demonstrated unique performance, suitable for developing various functional filtration products with broad applications.

Figure 4 Schematic diagram of the principle of acupuncture

1—fiber mesh; 2—needles; 3—mesh support plate; 4—mesh stripping plate

Vapes contain fewer harmful substances than traditional cigarettes, produce no odor, satisfy smokers' nicotine needs without generating toxic smoke, and reduce environmental pollution and secondhand smoke risks. Currently, genuine user demand provides sufficient market potential for Vapes, while government regulations normalize the industry and acknowledge its development. From these perspectives, the Vape industry is poised for long-term growth. Therefore, improving Vape filter materials to reduce harmful substance inhalation holds significant value. An industry's prospects depend not only on global changes but also on its internal evolution. If stakeholders in the Vape industry pursue reform and innovation to substantially lower harms and explore new paths, the industry's future could be even brighter.

Comment