ARE YOU OF LEGAL VAPE AGE?

Please confirm that you are of legal age to purchase vaping products to access our site.

Please confirm that you are of legal age to purchase vaping products to access our site.

Some items are no longer available. Your cart has been updated.

This discount code cannot be used in conjunction with other promotional or discounted offer.

Abstract

Introduction

1. Materials and Methods

2. Results and Analysis

3. Discussion

4. Conclusion

This article examines the heating structures of various electronic cigarette types and the temperature measurement positions in the atomization zone, with a focus on the atomization zone temperature testing for disposable Vapes. Through observational experiments on the heating positions of different heating cores, combined with electrical theory analysis, the optimal temperature measurement positions for the atomization zone in disposable Vapes are clearly defined.

As regulatory oversight of electronic cigarette products intensifies, the requirements for testing safety indicators in these products continue to escalate. According to the GB 41700—2022 "Vapes" standard implemented in 2022, the atomization zone temperature serves as a critical indicator for evaluating the quality and safety of Vapes, making it an essential item in product quality supervision and testing.

The operating principle of Vapes involves converting electrical energy into heat via heating wires and cores to atomize nicotine-containing liquids at high temperatures. Heating wires, made of metal, conduct current through the directional flow of free electrons. However, this flow encounters resistance within the metal, leading to energy consumption that manifests as heat, elevating the conductor's temperature. Joule's law quantitatively describes the relationship between conduction current and the heat generated in a conductor: Q = I²Rt, where Q is the heat generated, I is the current through the conductor, R is the conductor's resistance, and t is the energization time.

When the current through the conductor is constant, a larger resistance results in greater heating power and higher temperatures.

The heating module in Vapes can be modeled as a pure resistive circuit, adhering to Ohm's law, derived as R = U/I. Thus, the heating formula for a pure resistive circuit is Q = U²/R t, where U is the voltage across the conductor. With a constant voltage applied, a larger current or smaller resistance leads to greater heating power and higher conductor temperatures. During electronic cigarette use, sufficient high temperatures are required for effective atomization, yet temperatures must be controlled to prevent scalding injuries to consumers. Therefore, the atomization zone temperature is a vital safety technical indicator.

Appendix B of GB 41700—2022 "Vapes" specifies that high-temperature thermocouples should be affixed to the hottest spot on the electronic cigarette's heating element during atomization zone temperature testing, with the determination of this maximum temperature point being central to the test. Unlike replaceable cartridge Vapes, most disposable Vapes do not use ceramic cores; their heating devices typically consist of heating wires and cotton wicks. As a niche product in the domestic market, disposable Vapes exhibit varied heating zone morphologies. Currently, there is no explicit research on the maximum temperature point in the heating zone of disposable Vapes. This article investigates the atomization zone temperature measurement positions for two common shapes of heating cores in disposable Vapes.

Vapes operate by harnessing electrical energy to generate heat through heating elements such as wires and cores, enabling the high-temperature atomization of nicotine-infused liquids. The atomization zone temperature is pivotal for ensuring both effective performance and user safety, as excessive heat can pose risks like thermal injuries. This study addresses the gap in standardized measurement positions for disposable Vapes, focusing on their unique heating structures.

Test samples: Three different brands of disposable Vapes were used, with five samples prepared for each brand according to varying high-temperature thermocouple attachment positions.

Test materials: High-temperature adhesive, high-temperature thermocouples, and ethanol solution.

Instruments and equipment: Electronic cigarette temperature tester, programmable DC power supply, and high-temperature test chamber.

The atomization zone temperature was measured primarily using the thermocouple method, where thermocouples are connected to the heating positions to detect the maximum temperature during electronic cigarette operation. The thermocouples employed must meet Class 1 accuracy standards, with a temperature sampling frequency of no less than 10 Hz. Tests were conducted in an environment without forced air convection, at ambient temperatures between 15°C and 25°C.

Prior to testing, disposable Vapes were fully charged. Samples were disassembled, and e-liquids were removed before thermocouple attachment. The heating wire was extracted, and the thermocouple's metal probe was affixed to potential maximum temperature points using high-temperature adhesive. Adhesive application was controlled to ensure secure attachment without compromising measurement accuracy. Samples were left undisturbed for 24 hours to allow firm adhesion before proceeding.

The heating component of the test disposable Vapes consists of oil-absorbing cotton wrapped around the heating wire. The liquid atomizer in the cotton was first squeezed out, with remaining residues absorbed dry, followed by immersion in 75% ethanol solution for approximately 10 minutes. The plastic shell enclosing the wrapped cotton was also wiped clean with ethanol solution, immersed for 10 minutes, and then squeezed dry. Finally, the cotton was placed in an oven and baked for about 30 minutes until fully dry.

The dried cotton and securely attached heating core were reassembled to match the original disposable electronic cigarette configuration, taking care to protect the thermocouple attachment and lead wire exit points. The assembled sample with the thermocouple was fixed on the atomization zone temperature tester, and the thermocouple was connected to the instrument.

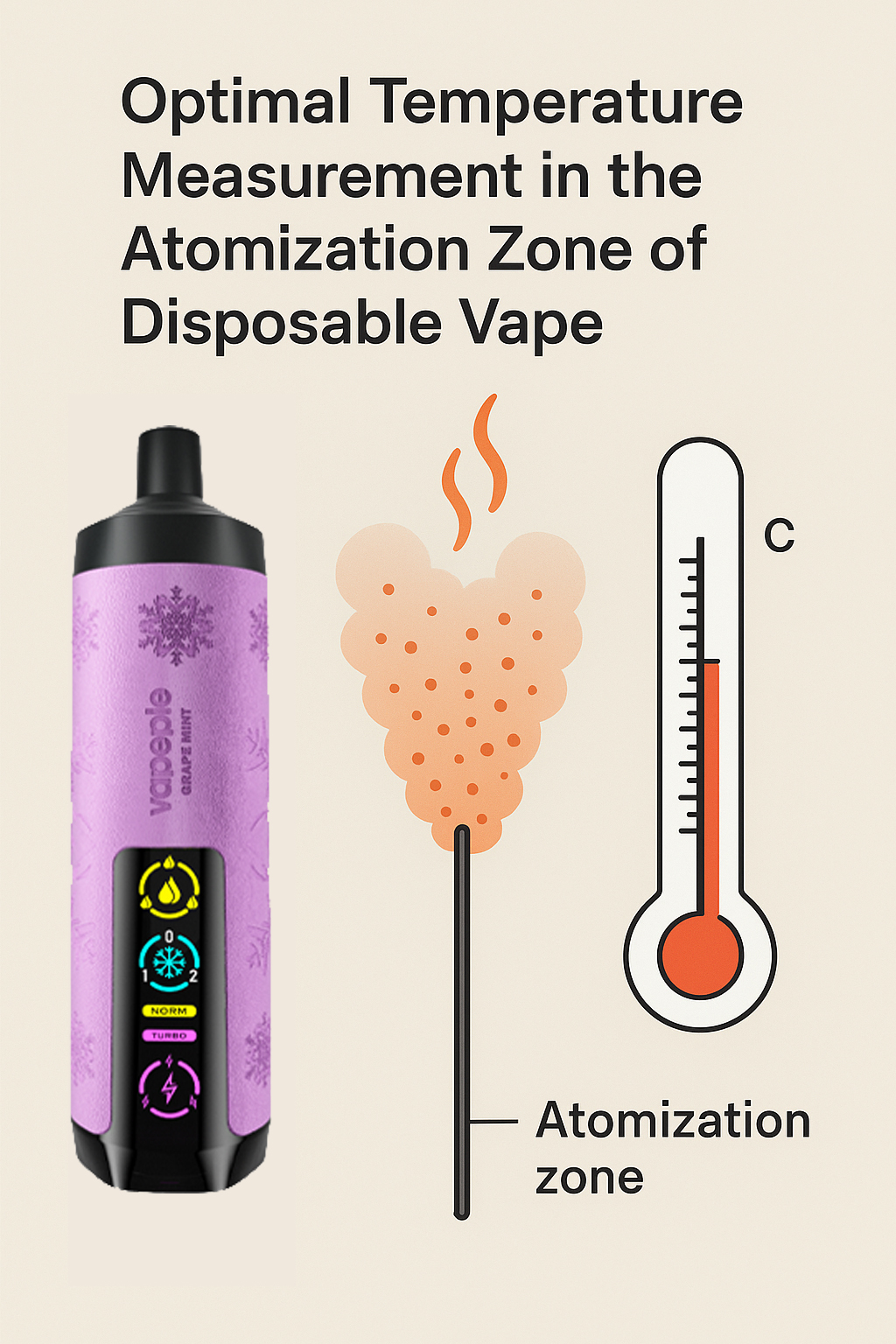

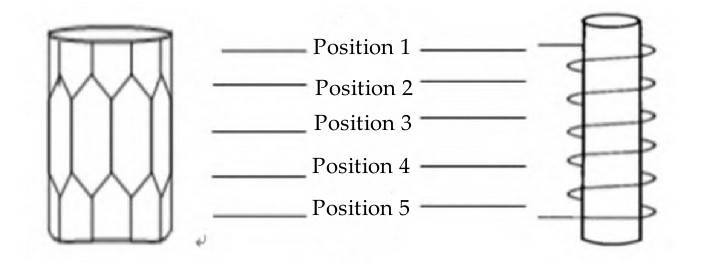

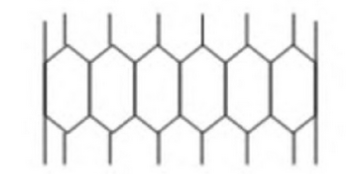

Upon disassembly and observation, the heating cores in disposable Vapes exhibit two structures: a mesh-shaped heating core as shown in Figure 1 (1), and a coil-shaped heating core as shown in (2). The heating device typically features a heating wire filled and wrapped in cotton wicks that absorb the atomizer liquid, with heat from the wire directly vaporizing the liquid in the wick.

Figure 1: Disposable electronic cigarette heating core structure

Figure 2: Mesh structure of mesh heating wire

The mesh-shaped heating core is common in disposable Vapes, where the finished core is often bent into a cylindrical shape and enclosed in a cylindrical cotton wick for uniform heating. Mesh heating wires commonly form a hexagonal network structure, as illustrated in Figure 2.

Disassembly revealed that Brands A and B of the tested disposable Vapes feature the mesh-shaped heating core from Figure 1, while Brand C uses the coil-shaped structure from Figure 2. For each brand, five samples were prepared with five different attachment positions, as marked in Figure 1 (positions 1–5).

Position 1 is the top heating area of the core; Position 2 is the upper-middle heating area, corresponding to the zigzag heating wire formed by the upper two edges of multiple hexagons in the mesh core; Position 3 is the middle heating area; Position 4 is the lower-middle heating area, corresponding to the zigzag heating wire formed by the lower two edges of multiple hexagons; Position 5 is the bottom heating area. Test results are presented in Tables 1, 2, and 3, respectively.

Table 1 /2 /3 Temperature detection results of the atomization area of brand A disposable electronic cigarette

| Sample Name | Test Location | Maximum Temperature |

| Brand A | Brand B | Brand C | Location 1 | 181°C | 225℃ | 181℃ |

| Brand A | Brand B | Brand C | Location 2 | 342°C |321℃ | 246℃ |

| Brand A | Brand B | Brand C | Location 3 | 256°C |233℃ | 328℃ |

| Brand A | Brand B | Brand C | Location 4 | 314°C |335℃ | 301℃ |

| Brand A | Brand B | Brand C | Location 5 | 203°C |187℃ | 214℃ |

For Brand A disposable Vape, the maximum temperature point is in the upper-middle heating area, specifically the zigzag position formed by the upper two heating wires of the hexagons, followed by the lower-middle area, then the middle area, with the top and bottom areas exhibiting the lowest temperatures.

For Brand B, the maximum temperature point is in the lower-middle heating area, specifically the zigzag position formed by the lower two heating wires of multiple hexagons, followed by the upper-middle area, then the middle area, with the top and bottom areas lowest.

For Brand C, using a coil-shaped heating wire, the maximum temperature point is in the middle of the coil-shaped wire, followed by the upper-middle and lower-middle, with the top and bottom lowest.

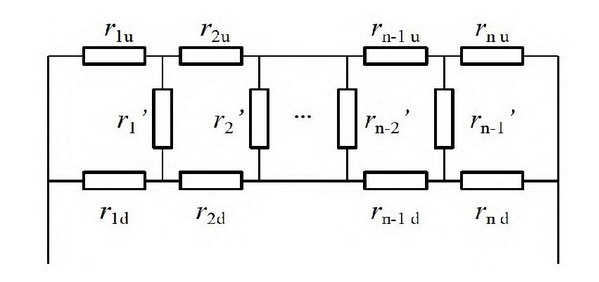

For mesh-shaped heating cores, the heating position is not at the center of the entire rectangle but at the two horizontal zigzag heating wires formed in the middle. The metal wires outside the upper and lower hexagons do not form a circuit, carrying no current and thus not contributing to heating. The conductors on both sides have minimal resistance and contribute negligibly to heating. The equivalent circuit of the heating core is shown in Figure 3.

Figure 3 Heating core equivalent circuit

This phenomenon is determined by the current distribution across the branches of the mesh heating wire. Given the uniform material, the resistances r_ku and r_kd of each segment in the upper and lower rows are similar. In practice, the potential difference across each vertical heating wire r_k is nearly zero, forming a balanced bridge where current through vertical wires is minimal, resulting in negligible heat. Upon activation, current primarily flows through the two middle horizontal zigzag heating wires, yielding similar heating power. Thus, these two zigzag heating wires reach the highest temperatures, with vertical wires mainly facilitating heat equalization. Additionally, due to larger heat dissipation areas on the sides, the maximum temperature occurs at the midpoints of these two zigzag rows.

For coil-shaped heating cores, formed by spirally winding the heating wire around the cotton wick and enclosed in oil-storing cotton containing e-liquid, the middle section of the heating wire exhibits the highest temperature. This is because the single heating wire forms a uniform current path, generating even heat along its length, but with higher heat dissipation efficiency at the ends. Therefore, the thermocouple should be attached to the middle during testing.

Through experimental observation and analysis of current flow directions, it is concluded that the maximum temperature point during electronic cigarette operation depends on the heating wire structure. For mesh-shaped heating cores, the maximum temperature point is on the branch with the highest current flow; in common hexagonal mesh structures, this is the midpoint of the two zigzag heating areas. For single-wire heating elements, the maximum temperature point is at the midpoint of the heating wire. When conducting atomization zone temperature tests on disposable Vapes, thermocouple attachment positions should be determined based on these findings.

Comment